Central Discharge Vibratory Screen Manufacturer & Supplier

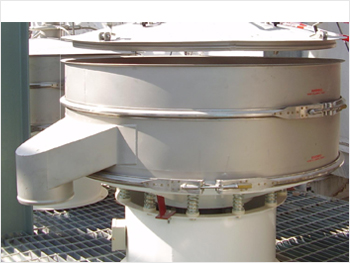

Central Discharge Vibratory Screen

Flow Separator has 2 Vibratory motors mounted either side of mesh Frame. Discharge of screening material getting from bottom. Advantage of this screening machine is direct vibration closer to mesh frame hence for more cycles per unit area, which helps 25% more productivity than standard vibratory screen and also lesser chances of mesh clogging. Looking to In-Line Packing process or material Flow Through between nos. of equipment. Here production does not allow screening separately for this purpose Nishi Techno Sys modified discharge of standard Vibro Screen. Cross Flow Separator useful in Food Industry, Chemical Industry and Pharmaceutical Industry. You can also install this screen above SILOs, Hopper, or you can directly pack solid screened material in to bags.

Applications

Industries we serve : Abrasive Industry, Paper mill Industry, Sugar Mill Industry, Ceramic tiles manufacturer Industry, Metal Industry, Food Powder Industry, Milk powder Industry, Mineral processors Industry, glass industry, Dyes industry, Detergent manufacturer Industry, ash Industry, cashew Industry, Biscuits manufacturer Industry, Resins Industry, Chemical Industry, Guar Gum Industry, Atta Industry, Masala Industry, Explosive Industry, Gelatine manufacturer Industry, Polymer Industry, Pharmaceutical Industry, Bulk Drug Industry etc.

Similar Products

Motorized Magnetic Seperator

Motorized magnetic separator which can be used online where the percentage of Iron Particles are more.

Vibro Shifter

Similar to Vibro Screen use wire mesh, perforated or slotted sheets for separation of material.

Gyro Shifter

Used in Abrasive, Papermill, Sugar Mill, Ceramic tiles manufacturer, Metal, Food Powder, Milk powder Industries etc.

Rotary Screen

We’ve developed it to overcome issues in Solid-Liquid process, this separator creates 3 plan motion gently vibration.